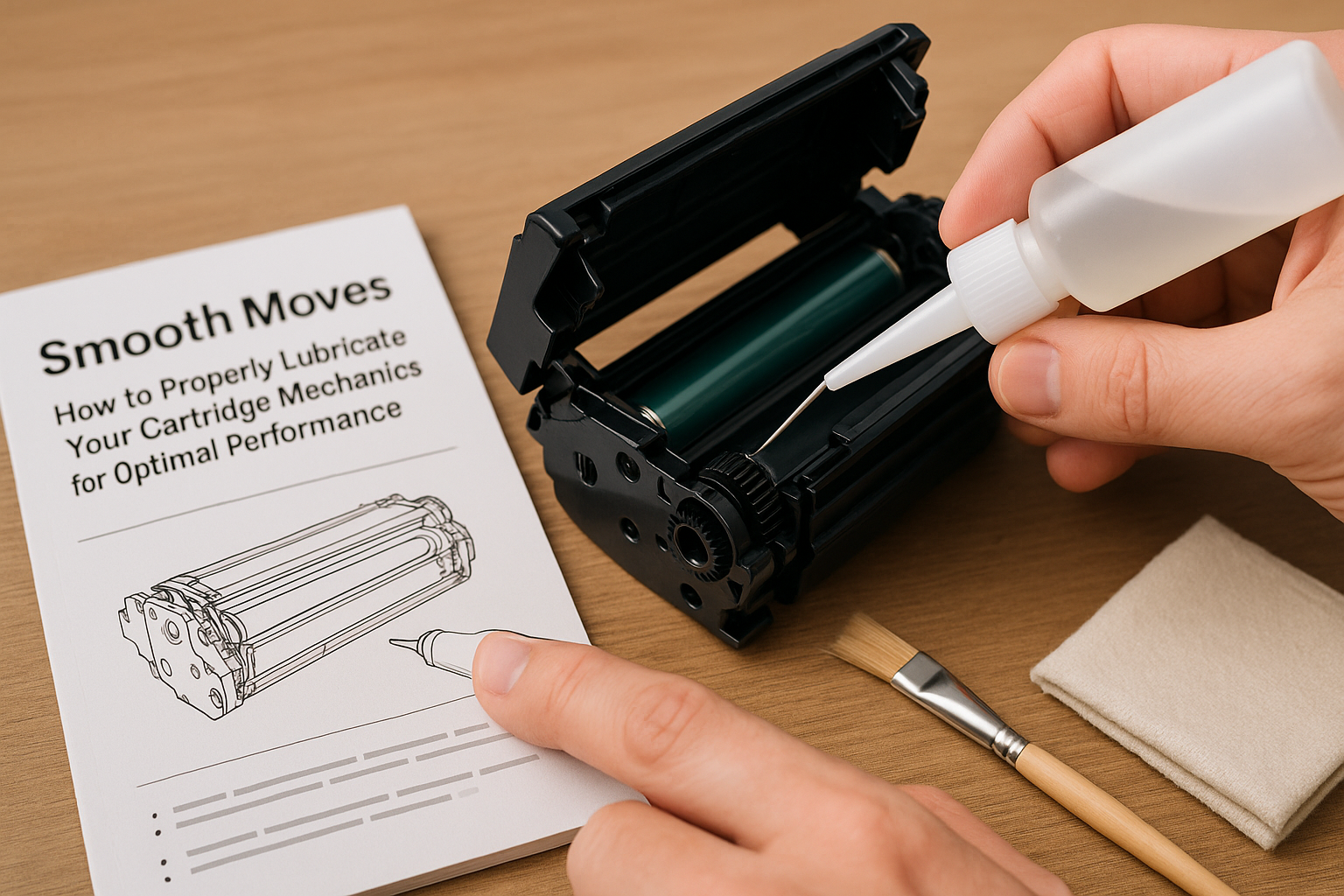

Immerse yourself in the symphony of gears and rotors, the orchestrated dance of mechanical parts, and the unrivalled satisfaction that comes from a machine operating at its peak. These are all elements of a well-oiled cartridge mechanic – a metaphorical representation of an optimally functioning and well-lubricated machine. Welcome to “Smooth Moves: How to Properly Lubricate Your Cartridge Mechanics for Optimal Performance”, a comprehensive exploration into the often-underestimated importance of lubrication for your cartridge mechanics. This article is designed to intrigue, educate, and ultimately assist you in achieving the highest degree of efficiency and longevity from your machinery.

In the intricate world of machinery, the importance of proper lubrication can often be overlooked. Yet, it plays a vital role in not only the smooth operation of the mechanical parts but also in their lifespan, maintenance costs, and overall performance. A well-lubricated machine is like a well-oiled athlete – it performs at its peak, reduces the risk of wear and tear, and continues to run efficiently over a long period. It’s a science and an art, and this article is your guidebook into the fascinating world of lubrication.

In the upcoming sections, we’ll be delving into the specifics of why lubrication matters and how it contributes to optimal performance. You’ll gain insights into the different types of lubricants and their applications, the art of choosing the right lubricant for your cartridge mechanics, and step-by-step guidance on how to properly lubricate your machinery. This article is more than just a dry technical manual; it’s a riveting journey into the heart of your machinery, a testament to the marvel of engineering, and a tribute to the enduring pursuit of perfection. So, buckle up and prepare for a fascinating exploration into the world of lubrication and cartridge mechanics. You’re in for a smooth ride!

Understanding Cartridge Mechanics

The intricacies of cartridge mechanics may seem daunting at first glance, but with a little bit of knowledge and the right tools, it can be a straightforward process. The cartridge system in any mechanical device, be it a printer, a vehicle, or an industrial machine, serves as the ‘heart’ of the operation. These systems house the vital components that allow the device to function optimally. To ensure these systems perform at their best, regular maintenance, including proper lubrication, is essential. The aim is to reduce friction, which can wear down parts over time and cause device malfunction.

Just as our bodies need water to prevent dehydration, cartridge mechanics need lubrication to operate smoothly. It’s not just a matter of adding oil or grease; the type and amount of lubricant can significantly impact the overall performance of the device. Using the wrong kind can cause more harm than good, and not enough can result in excessive wear and tear. Therefore, understanding the correct lubrication methods is crucial.

But what exactly should you look for in a lubricant? How often should you lubricate your cartridge mechanics? What are the steps involved in the process? In this article, we’ll delve into these questions, offering a comprehensive guide to effectively lubricating your cartridge mechanics for optimal performance.

Choosing the Right Lubricant

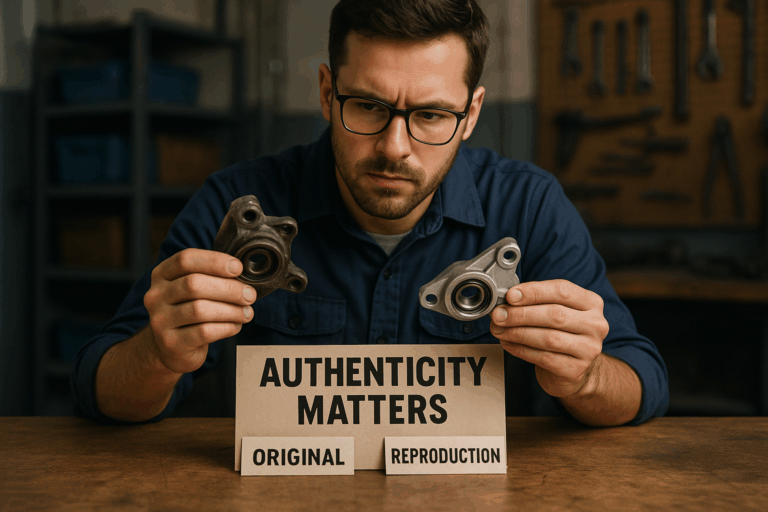

When it comes to lubrication, one size certainly does not fit all. There are a myriad of lubricants on the market, each with its unique composition and purpose. The first step in correctly lubricating your cartridge mechanics is selecting the right lubricant. The choice will depend on several factors, including the type of device, the materials involved, operating conditions, and environmental factors.

While oil is a common choice for many due to its ability to reduce friction and dissipate heat, it may not always be the best option for cartridge mechanics. Grease, with its higher viscosity and ability to stay in place, might be a better choice in some situations. Besides, there are specialty lubricants specifically designed for certain applications.

Take a look at the comparative table below to understand how different types of lubricants stack up:

| Type of Lubricant | Advantages | Disadvantages |

|---|---|---|

| Oil | Excellent at reducing friction and dissipating heat | Can leak and require more frequent application |

| Grease | High viscosity, stays in place longer | Can attract dust and other contaminants if not properly sealed |

| Specialty Lubricants | Designed specifically for certain applications | Can be more expensive and harder to find |

Knowing When and How to Lubricate

Just like any maintenance task, timing is everything. Lubrication isn’t a one-and-done deal—it’s a recurring task that should be done at regular intervals to ensure smooth operation. The frequency depends on several factors, including the type of device, its usage, and the operating environment. For example, a cartridge mechanic in an industrial setting may need more frequent lubrication than one in a home printer due to the harsher conditions and higher usage.

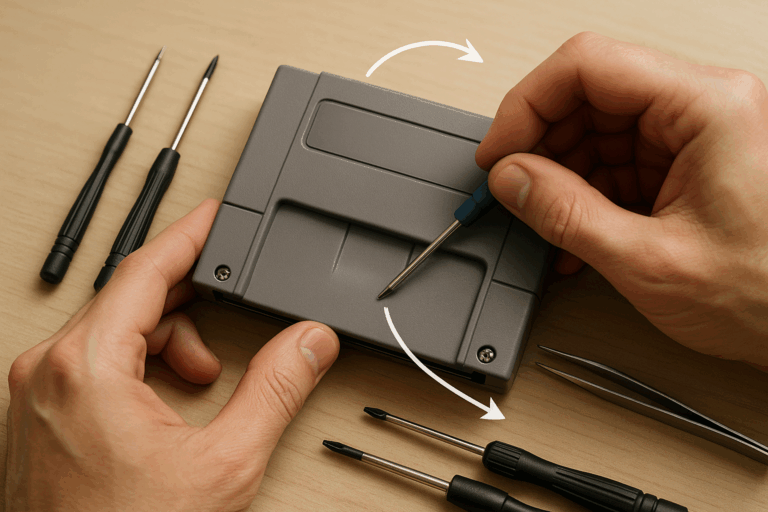

The process of lubrication itself is not overly complex, but care should be taken to ensure it’s done correctly. You’ll need to clean the parts before applying the lubricant to prevent dust and debris from causing damage. The lubricant should be applied evenly, ensuring all the moving parts are well coated. Over-application should be avoided as it can lead to waste and potential issues with performance.

To better understand the lubrication process, watch the video ‘How to Lubricate Your Cartridge Mechanics’ on the ‘Mechanical Engineering 101’ YouTube channel. This step-by-step guide will take you through the process, demonstrating best practices and offering tips for success.

Proactive Maintenance: Key to Longevity

Proper lubrication is just one aspect of maintaining cartridge mechanics. Regular inspections, cleaning, and replacement of worn parts are also essential to keeping your device in top condition. It’s worth noting that while reactive maintenance (fixing things when they break) is sometimes necessary, a proactive approach is far more beneficial in the long run.

Proactive maintenance helps to identify potential problems before they cause a breakdown, reducing downtime and repair costs. It can also extend the lifespan of your device, giving you a better return on your investment. So, don’t wait for a problem to manifest before you take action. Regularly inspect your cartridge mechanics, keep them clean, and lubricate them as necessary.

To sum it up, proper lubrication of your cartridge mechanics is vital for optimal performance. By choosing the right lubricant, knowing when and how to apply it, and adopting a proactive approach to maintenance, you can keep your device running smoothly and efficiently for years to come. Remember, a little bit of care can go a long way!

Conclusion

In closing, the comprehension of cartridge mechanics, specifically in regards to their lubrication and maintenance, is instrumental for ensuring the optimal performance and longevity of mechanical devices. This understanding eliminates the seeming complexity and transforms it into a manageable and straightforward routine.

Lubrication in cartridge mechanics is akin to hydration in the human body; vital, consistent, and impactful. The choice of lubricant carries significant weight in the overall performance of the device, and its quantity and quality can make the difference between a smoothly operating machine and a malfunctioning one. From oils to greases to specialty lubricants, each type offers unique benefits and potential drawbacks, making their selection a careful process dependent on the specific device, its materials, operating conditions, and environmental factors.

Not just the selection, but also the method of lubrication plays a pivotal role. Timing is essential. Regular intervals of lubrication, tailored to the device’s usage and environment, ensure smooth and consistent operation. The application process, while not overly complex, demands a careful hand to prevent damage from dust and debris and ensure an even coating on all moving parts.

Maintenance, both proactive and reactive, is crucial in the care for cartridge mechanics. Regular inspections, cleaning, and replacement of worn parts extend the device’s lifespan and prevent the potential for breakdowns. Proactive maintenance, in particular, identifies potential problems before they escalate, reducing both downtime and repair costs.

Consider, for example, the application of these principles to the lubrication of a cartridge mechanic in an industrial machine or a home printer. Choosing the right lubricant, understanding when and how to apply it, and implementing a consistent schedule for inspection and cleaning will ensure that the machine runs smoothly and efficiently, giving you a better return on your investment.

In the words of Benjamin Franklin, “An ounce of prevention is worth a pound of cure.” This certainly holds true in the realm of cartridge mechanics. Regular maintenance, coupled with a proactive approach, can prevent significant issues down the line.

To delve further into this topic, consider resources such as the ‘Mechanical Engineering 101’ YouTube channel, which offers informative videos like ‘How to Lubricate Your Cartridge Mechanics’. Make use of such resources to expand your knowledge and expertise.

Finally, remember that your input and experiences are valuable. Feel free to share your insights, thoughts, and questions in the comment section. This information not only helps you but also aids others in the community.

In conclusion, the proper care and maintenance of cartridge mechanics can significantly extend the life of your device and improve its performance. As with many things in life, a little knowledge and a proactive approach can go a long way.

So, whether you are a professional engineer or a curious enthusiast, embrace the opportunity to learn, apply your knowledge, and share your experiences. The world of cartridge mechanics is waiting for you. Happy learning, and happy lubricating!